Real-time production control

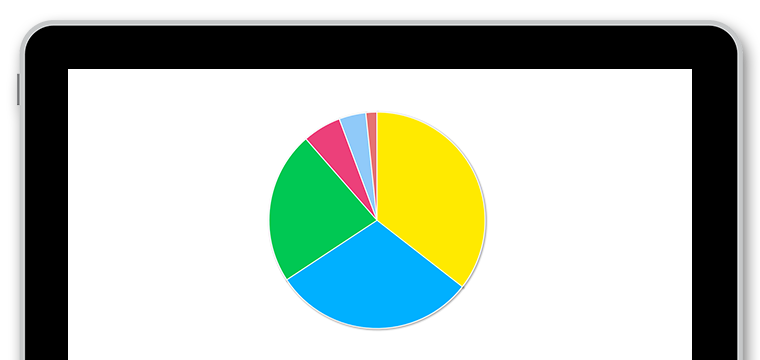

doeet allows a complete production control and monitors in real time all the activity of your machines: stops, speed, units produced, quality, and compiles all these data in graphs for easy analysis.

doeet is a comprehensive OEE MES and MOM system and one of the leading Industry 4.0 platforms for production control, productivity improvement and cost reduction.

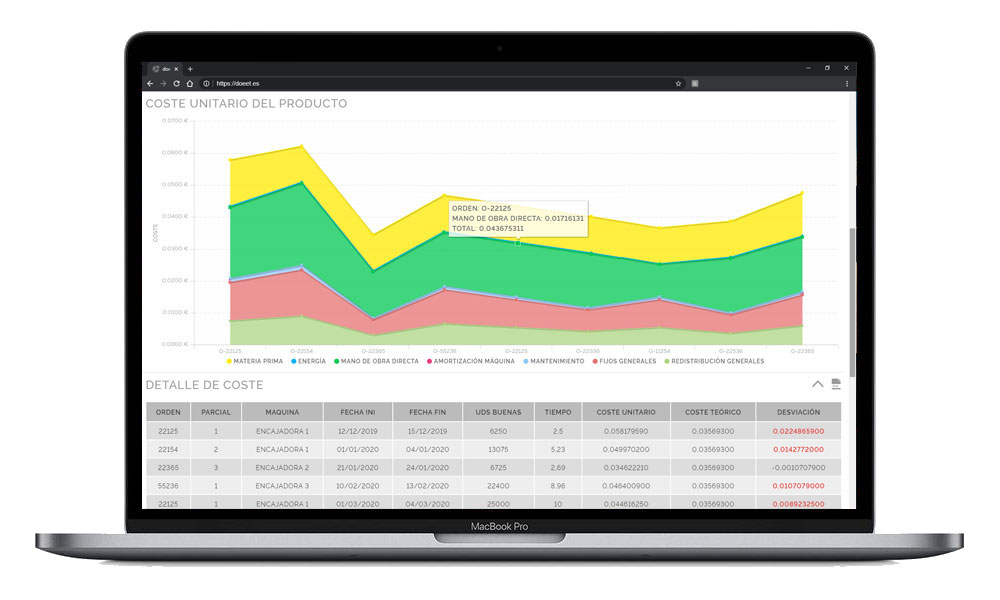

doeet collects your manufacturing data in real time: production, productivity, quality, traceability, costs, and analyzes machine and operator information: stoppages, units produced, consumption, scrap, wastage… doeet records quality controls or manufacturing parameters, ensuring advanced traceability of your entire production.

Consulting doeet reports allows you to analyze the current status of your production and take the necessary measures to improve it.

Digitize and optimize your processes

Increase your productivity and reduce costs

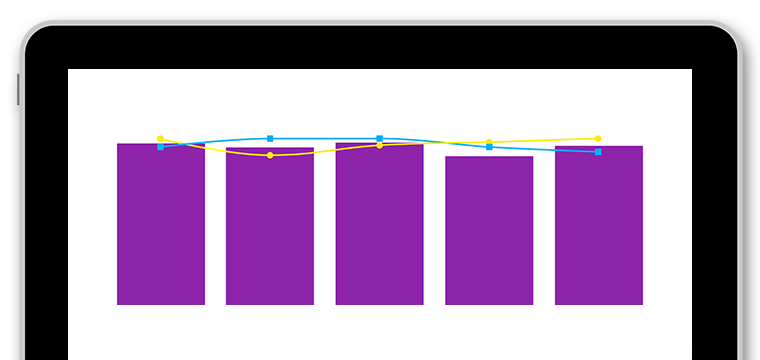

doeet has a double functionality: to control production in real time and to know the deviations of OEE productivity (actual production vs. expected production).

To to know in real time and reliably the causes that have prevented the expected production, the doeet system allows take prompt action to correct the results by analyzing, together with the personnel involved, the results obtained and the need to make changes oriented towards the productivity improvement and cost reduction.

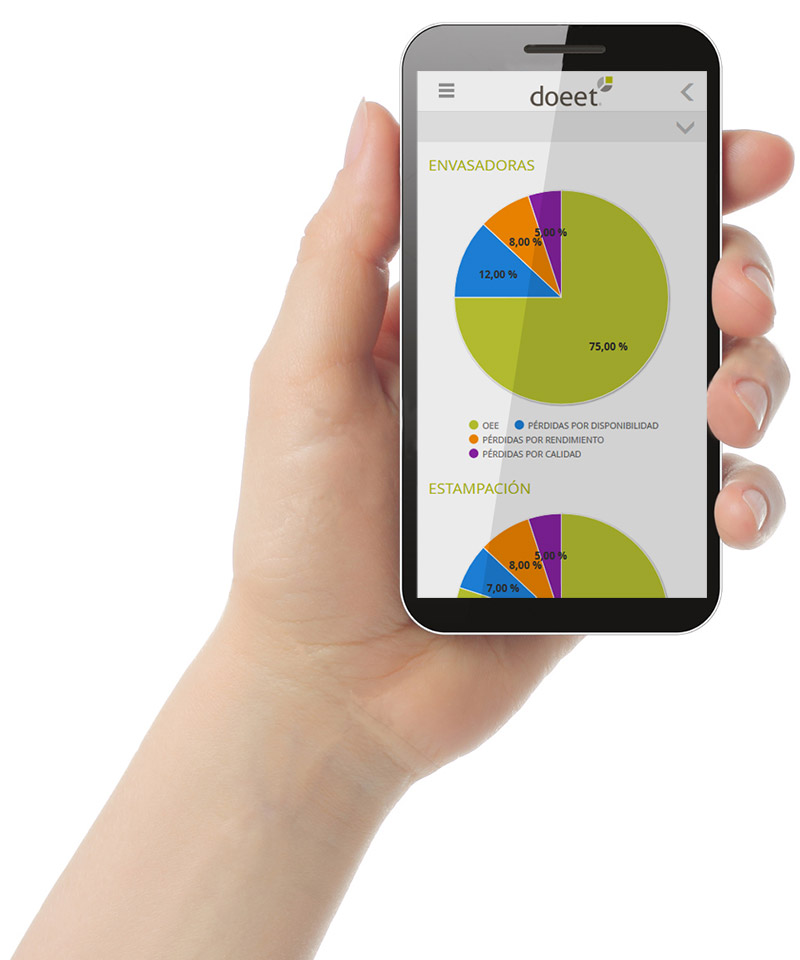

Production control in real time and in any location

All your production in the palm of your hand

Mobile technologies and HMI interfaces make it possible to consume the information coming from the different systems, displaying it on the plant floor on devices such as tablets, mobile devices and all types of screens.

doeet is developed on the most advanced web standards that allow us to access the required information from anywhere and from any Android, Windows or Mac device.

100% reliable and objective data

Control of production, productivity, machines and operators

Operator information

Know which operator is on the machine and which reference is going to be manufactured. Or if the machine is stopped, what is the reason.

All these operations are performed from the doeet HMI terminal, equipped with customizable software in which the operator enters the required information in a few clicks: shift change, production order completion, stops, checklists or checklists.

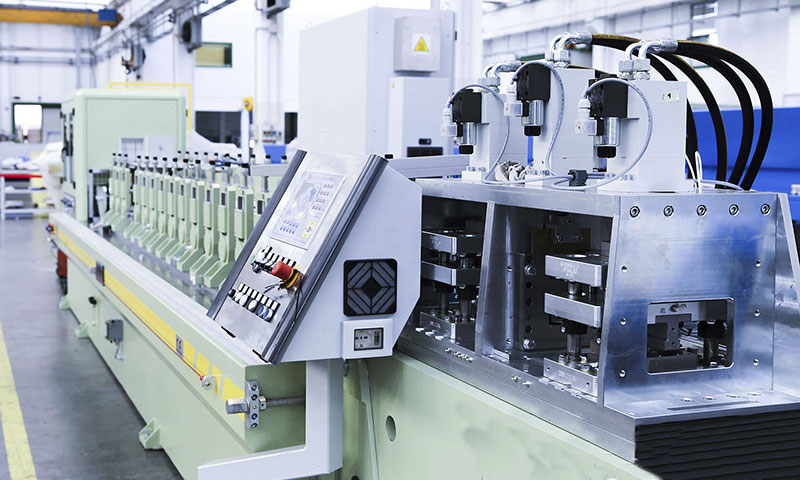

Machine information

doeet obtains the information on machine stops or speed by taking advantage of the systems already integrated. When this is not the case, we incorporate different sensors or external signal controllers, which centralize the information in the PLC cards.

With this integration we already have all the machine data monitored. These elements constitute the in-plant data capture of the MES system doeet.

Fully customizable production control

The whole system tailored to your needs

doeet has predefined reports for production and productivity control, operator HMI terminals and other functionalities commonly used in the industry. You can filter the data by line, shift, or reference and define the time interval. And save the filters you use most frequently.

Configure your own causes for stoppages or scrap so that the operator can justify them easily and quickly at the machine.

You can also add our optional modules at any time. Or request a specific development to adapt the system to your way of working.

Industry 4.0, Production Control, Smart Factory, Business Intelligence

Orient your industry towards the future

The new Industry 4.0 solutions facilitate intercommunication between management systems and manufacturing plants in real time and make it possible to multiply the volume of information analyzed and correlated in real time.

Intelligent analysis of production data or Smart Factory enables early detection of errors or failures in the manufacturing process and establishes an intelligent problem solving mechanism.

Business Intelligence is to transform data into information and information into knowledge, knowledge that is used to optimize business decision making based on objective data.

We are committed to your improvement

Guaranteed return on investment

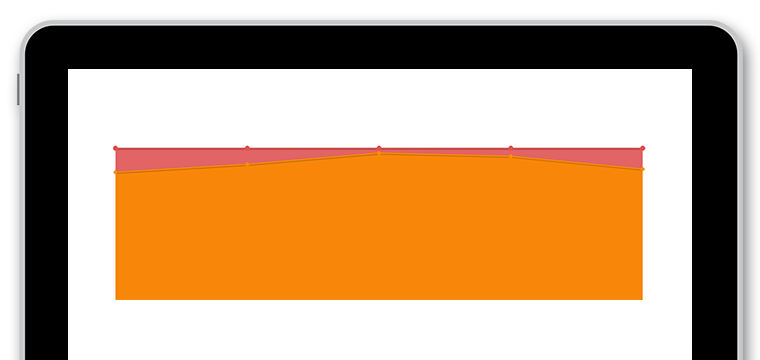

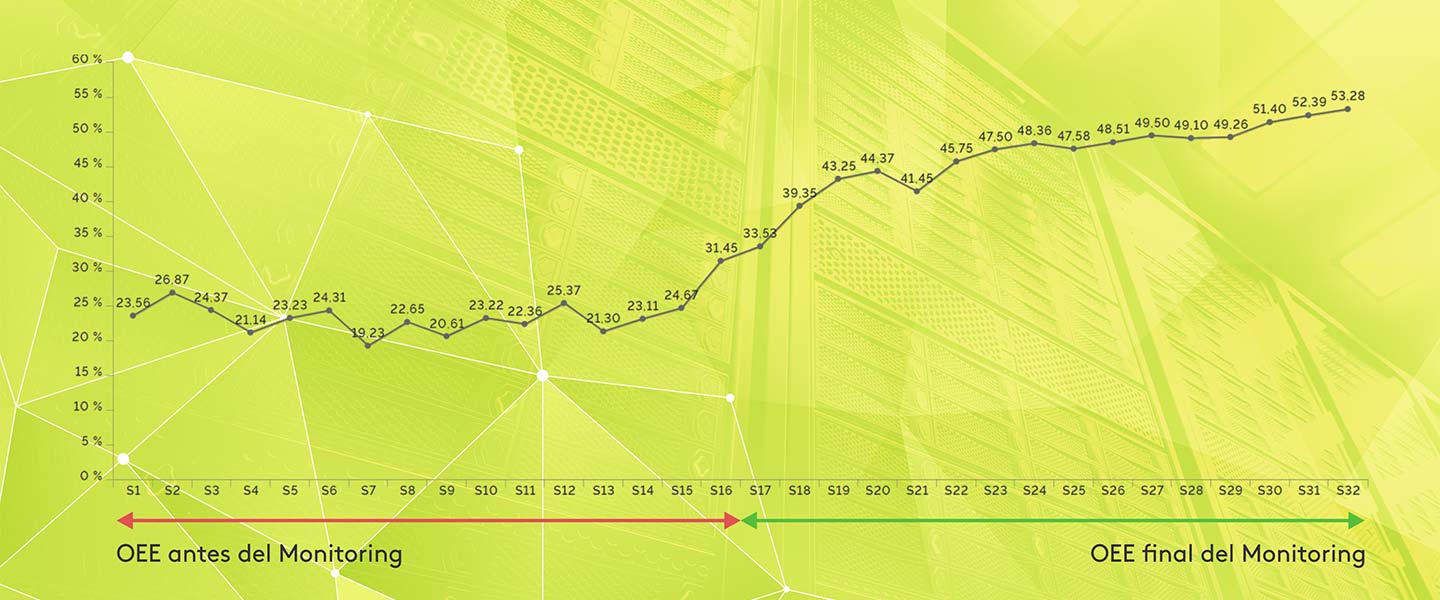

OEE evolution with doeet before and after monitoring

All doeet implementations include a monitoring phase with our experts in Industrial Organization, so that you can take advantage, from the first moment, of all the information provided by the system for the analysis of your productivity level and cost reduction.

The Productivity Committee, a multidisciplinary team with the areas of Production, Maintenance, Improvement and Management, together with our experts, analyzes the data and detects the causes of low productivity and its economic impact, and proposes improvement actions to increase productivity.