Calculation of OEE in production

Measure the overall efficiency of machines and operators with the calculation of OEE in production and productivity KPIs.

Know your real productivity

OEE in production (Overall Equipment Efficiency) provides a global view of the productivity losses that occur during manufacturing processes.

The OEE doeet system collects all the data from your production lines and executes the necessary calculations to obtain the OEE, availability, performance and quality values, their deviation from their target value and their evolution over time.

Measure, manage, improve your OEE in production

Know exactly which OEE indicator is affecting your production efficiency when it occurs and for what reason.

Analyze the actual evolution of the productivity indicators and compare them with the established objectives. So you will be able to know if a drop in production is due to a downtime or speed problems in the machines, or quality problems in the final product.

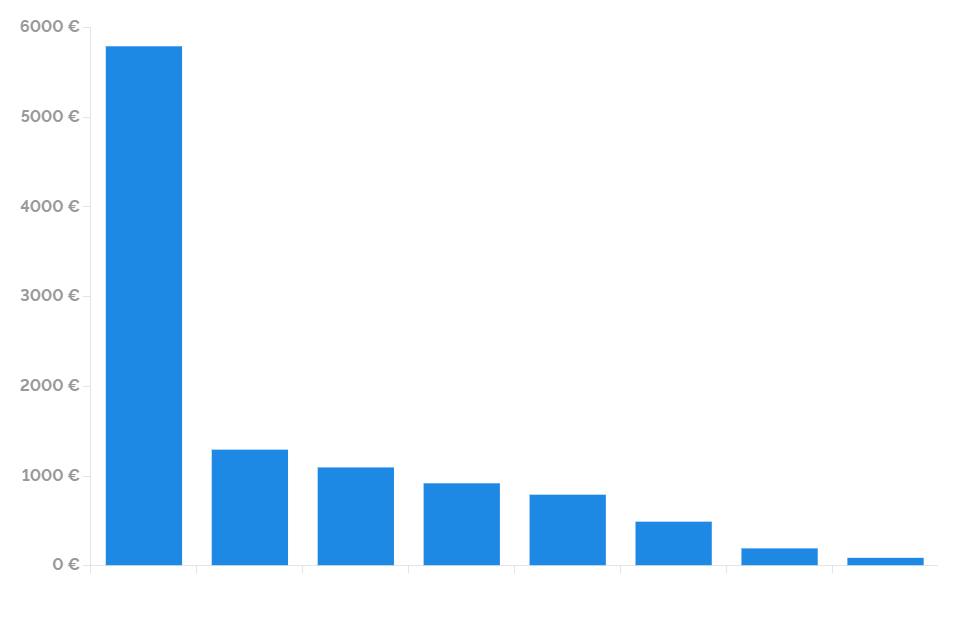

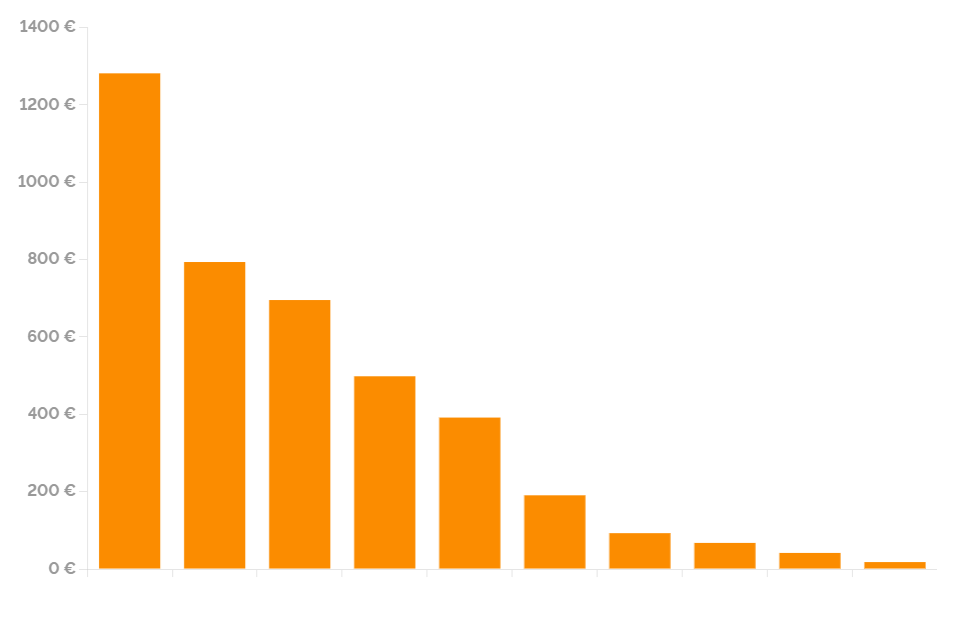

Control downtime on your lines

Analyzing the most common causes of the machine and operator downtimes and taking measures to avoid them will increase the availability of your machines and operators and improve your productivity.

Customize the most common causes of stoppages in your production and group them into categories; so that it’s easy for the operator to rapidly justify the stoppage at the machine via the doeet terminal.

Your factory at high performance

Doeet automatically counts all units produced through sensors integrated into the machines or external PLC cards.

The system recognizes the changes in times of references and calculates the average speeds for each one and their deviations from theoretical speeds so that you know your precise performance.

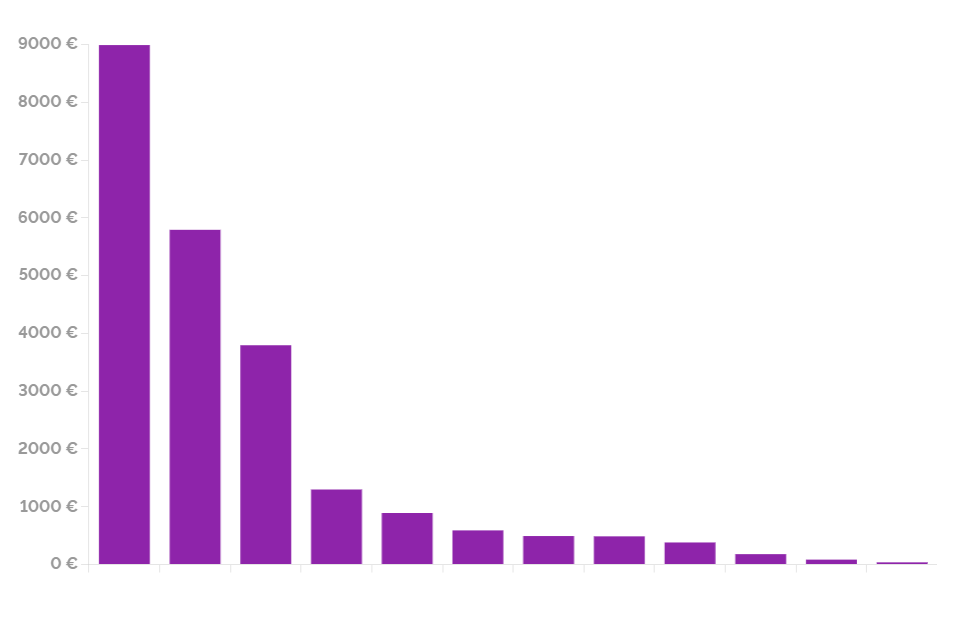

Manufacture without defects and without scrap

Count the products without defects against the total number of products manufactured, know the causes of failures and take measures to reduce them and avoid rework.

Quality losses involve both energy and raw material costs as well as production time and reprocessing losses, in addition to the cost of discarding or recycling defective units.

All your data at a glance

Doeet has several predefined productivity reports ready to start analyzing your production: OEE, availability, performance and quality. Reports are designed to range from general analysis to particular detail in a few clicks.

Customize and filter all your production data by line, reference, order, and shift, to study in more detail the causes of lost productivity.

100% reliable and real-time data

Doeet obtains data directly from the machines (running times, downtime, units produced) so that production records are reliable and cannot be manipulated by the operator.

Knowing in real-time and reliably the drops in production and their causes enables us to take measures aimed at improving productivity. Once the measures have been implemented, we will review the data to verify if we have solved the problem.

Advantages of OEE calculation in production

Analyze your production in real time with OEE indicators.

Filter production data by line, reference, order or shift.

Know the hours of walking and stopping, their causes and frequency.

Know the actual units manufactured on each production line.

Diagnose in which shift the speed drops of the operator or the reference.

Analyze your quality and the reasons for defective units.

Functions of OEE calculation in production

- Analysis of the global state of production with OEE indicators.

- Comparison of actual and theoretical production data and their evolution.

- Calculation of costs due to downtime or loss of yield and quality.

- Control of machine and operator status: running, stopped, non-operational, and analysis of causes of stoppages.

- Registration of units per machine, hour, reference, and operator.

- Justification of defective units and analysis of scrap causes.

Other solutions for Operations Management, Factory Plant and Cost Control