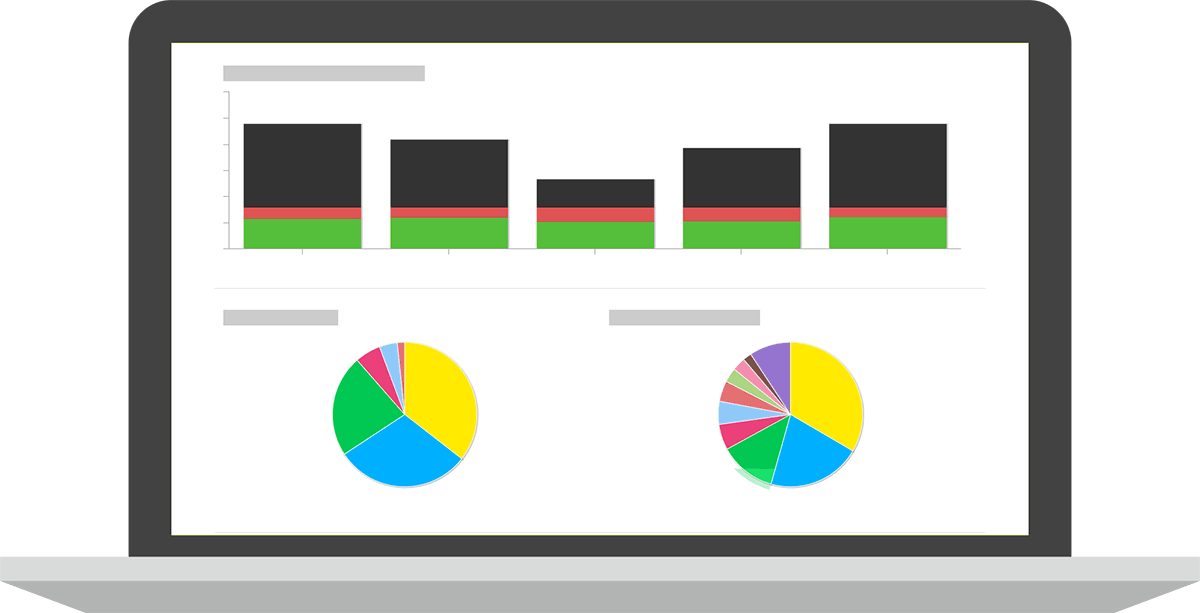

Molds and tooling control

Manage auxiliary tools with molds and tooling control, and apply the poka-yoke system in the factory plant.

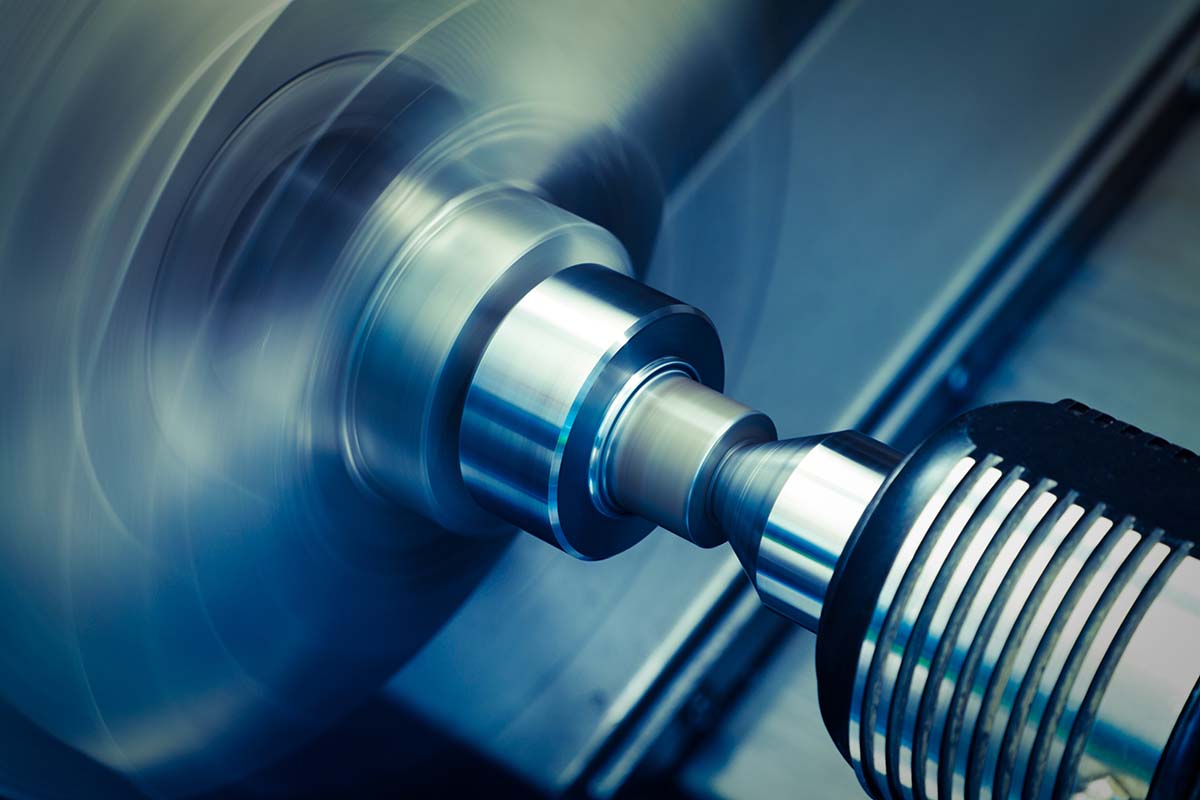

Register your molds and tools

Record each of the tools used in your production processes. Indicate for each one of them its registration number, the date of registration and the maximum number of parts or hours it can manufacture.

Your tools organized

Create a tooling plan to group the tools used in your production processes according to their specific characteristics and apply the 5s methodology, to achieve better organized, tidier and cleaner workplaces, higher productivity and a better working environment.

Group all the tools by machine to facilitate optimal tooling control on the factory plant.

Record the wear and tear of each tool

Doeet records the number of hours each tool has been used and the number of parts it has produced. In this way, we will only replace the tool when it has reached its wear limit, to avoid the production of defective units.

Poka-yoke system to avoid assignment errors.

When loading an order into a machine, a prompt will indicate to the operator whether or not the molds being used are compatible with the machine. In this way, it will not be possible to start manufacturing orders with incorrect molds.

Advantages of Molds and Tooling Control

Register and enrol all your tools and molds.

Take total control of your tools digitally.

Replace your molds and tools before their wear limit.

Avoid manufacturing errors due to the use of wrong molds.

Molds and Tooling Control Functions

- Registration of tools and tooling required in the plant.

- Registration of injection molds and presses.

- Control of the hours and parts produced with each molds or tool.

- Poka-yoke system to avoid assignment errors.

Other solutions for Manufacturing Operations Management, Warehouse and Traceability