Manufacturing control parameters

Control of manufacturing and critical parameters to avoid bad units due to machine failures or misalignments.

Monitor key manufacturing control parameters

Analyzing machine variables and their records is essential for detecting deviations in the production process, machine downtime and avoiding the manufacture of defective units.

Define the set of variables that affect your production and monitor machine parameters such as temperature, pressure or current in real-time. Configure as many manufacturing parameters as you need and link them to the corresponding machines.

Parameters associated with the production order

Doeet associates the manufacturing parameters to the current work order and the events recorded during its reading.

The inverse analysis allows knowing if the machine parameters were correct during the execution of the order, or if any variable was out of range and has caused the production of defective units.

Enable automatic records and don’t lose any data

By enabling an auto-recording, the variables associated with the machine are automatically recorded in the doeet system by the sensors connected to the PLC.

We can group variables and configure their checking and logging frequency.

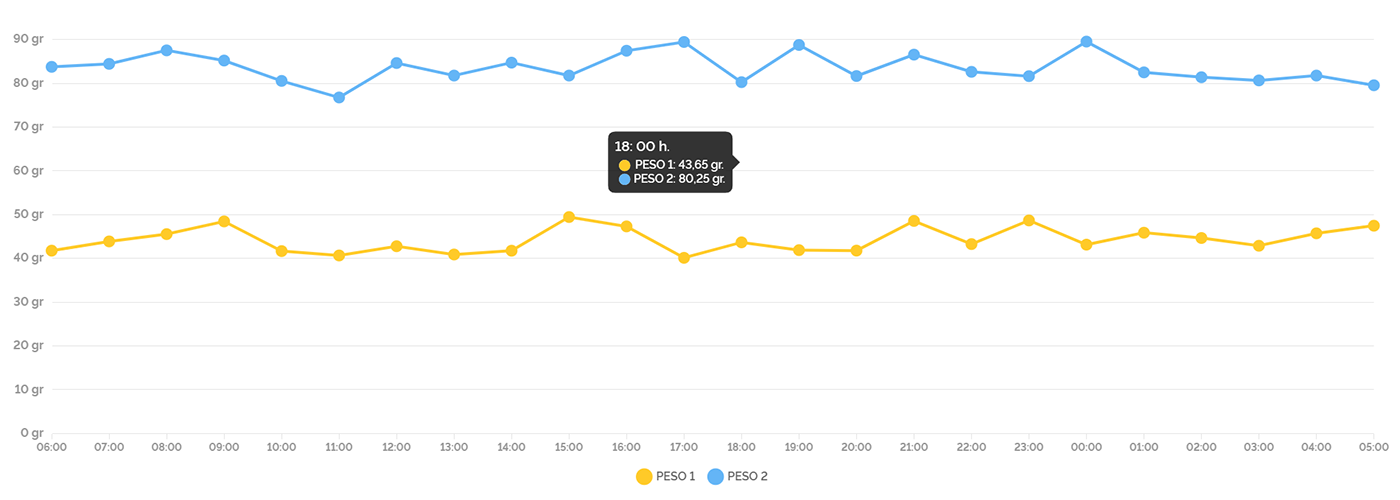

Visual graphics for each manufacturing control

Doeet generates control charts with the values taken by each of the variables and their evolution over time.

All this information can be accessed from the manufacturing parameters report or operator HMI.

Create warnings and alerts for out-of-range parameters

Create a serie of alarms that are triggered when any machine parameter falls outside a defined minimum and maximum tolerance range.

When the alarm is activated, it will display a warning on the operator terminal when the parameter goes out of the optimum range set for production. This way we avoid producing bad units due to machine failures or misalignments.

Advantages of manufacturing control and parameters

Set up manual and automatic records of your critical manufacturing parameters.

Real-time graphical monitoring of parameter values.

Set warnings and alarms for early detection of faults and malfunctions.

Reduce your scrap, waste and rework by manufacturing with out-of-range parameters.

Manufacturing control functions and parameters

- Classification of production variables: temperature, pressure, current.

- Association of records to production orders, raw materials, and batches.

- Generation of reports and control charts in real-time.

- Alerts and alarms based on a maximum and minimum range of tolerances.

- Display of machine parameters on the operator terminal.

- Automatic recording of parameters.

- Historical records of the variables.

Other doeet solutions for Factory Plant Control