MES ERP Integration

The MES ERP integration allows sending work orders and knowing their status and consumption in real-time.

MES system with MES ERP integration

The MES ERP integration of the doeet MES system allows companies to improve reaction times and avoid rework in terms of allocating consumption and hours spent on each work order.

By connecting these systems we obtain production data in real-time, reliably and objectively, and the production reports are 100% digital.

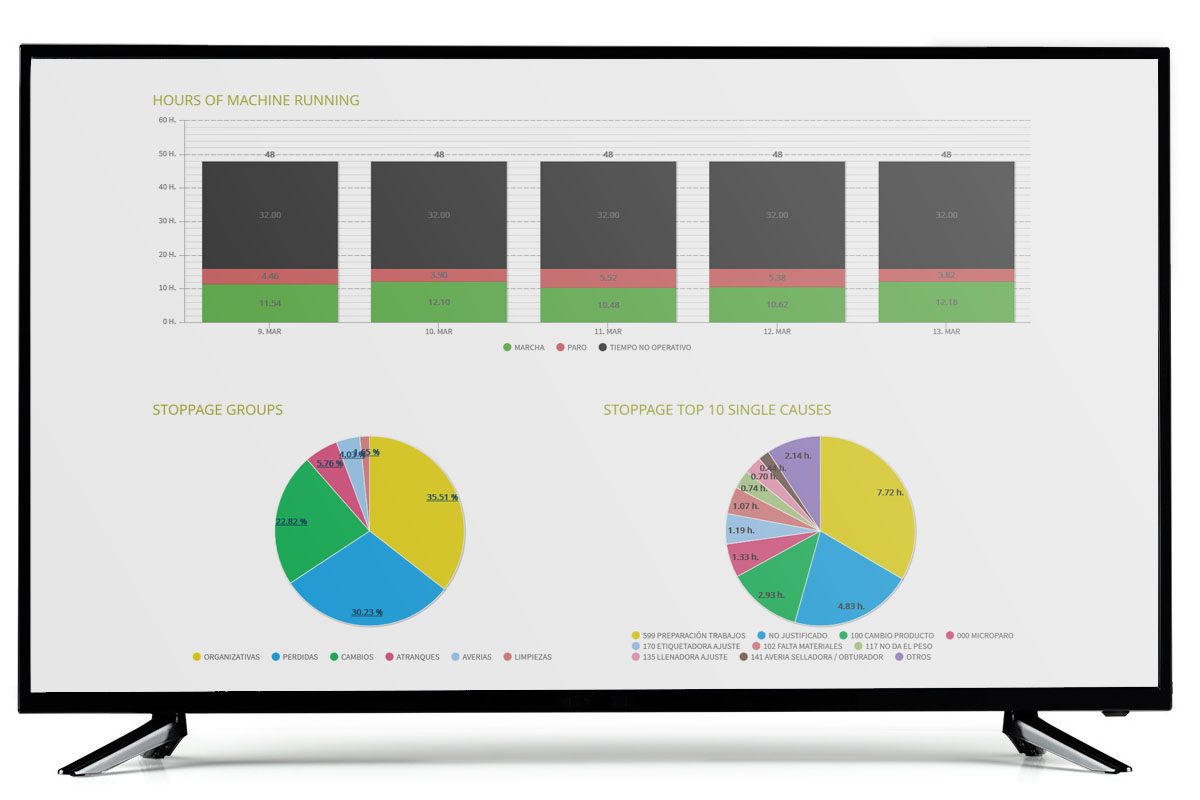

Availability and downtime report

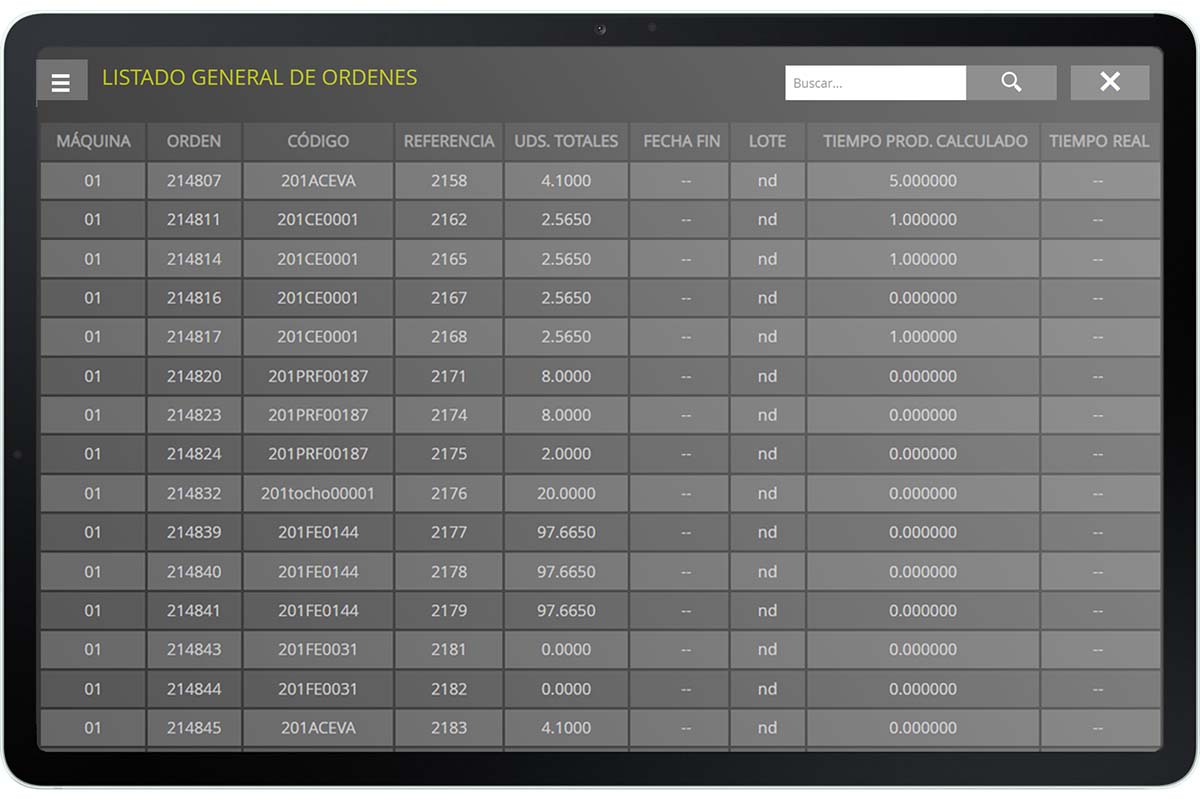

Operator’s tablet with the list of orders to be manufactured

Send the day’s production orders to each work centre.

Doeet collects from the ERP the information required in production and sends it to the operator terminals at the machine.

All the data necessary for production are associated with the order: article code, units, theoretical production times or machine parameters.

MES ERP integration with real-time order status

Doeet collects plant production data and returns order status to the ERP in real-time. This enables you to know at all times which orders are planned, in process, completed, on hold or blocked to react quickly.

Know the actual raw material consumption and production times for each order to analyze any discrepancy with the theoretical times in the production reports.

Advantages of MES ERP integration

Send orders to be manufactured directly to the operator in the factory plant.

Know in real time the status and actions performed for each work order.

Automatically receive in the ERP all data collected in order.

Anticipate the supply of materials by knowing the actual consumption.

Eliminate paper generated by the management of production orders.

Compatible with the main ERPs on the market

Upload consumption, labels and working documents

Attach to each order the details of the batches and expected consumption of raw materials or semi-finished products. This way you can control your stocks and obtain complete traceability.

Send with the order the labels to be printed with all the details of the order, and any other data that may be required in production.

Modify work orders and communicate them instantly

Sometimes we need to reorganize production and meet unforeseen orders or emergencies. Doeet allows partial closures of work orders to execute the next one or another with higher priority.

Send order modifications with one click and they will be instantly visible to managers.

MES ERP integration functions

- Import of manufacturing orders to MES doeet from ERP.

- Import of consumptions, labels and documents associated with the order.

- Real-time data back to ERP: order status, costs, raw material consumption, quality.

- Automatic loading of orders.

- Sending manufacturing parameters and incidents to the ERP.

Other doeet solutions for Operations Management, Factory Plant and Cost Control, Traceability and Warehouse