CMMS Maintenance

Manage and plan the CMMS maintenance of your plant and avoid shutdowns due to breakdowns, lack of maintenance or spare parts.

Schedule your preventive maintenance

Create the necessary preventive maintenance programs for all your machines and installations simply and efficiently. Good preventive maintenance aims to reduce breakdowns and downtime to improve productivity and reduce costs.

Indicate the frequency of preventive maintenance. Maintenance orders are automatically generated and assigned to the corresponding mechanic. The orders will appear in the mechanics’ task list on the date indicated and with the corresponding priority.

Keep track of your spare parts at all times

Warehouse and stock management controls the quantity, status and location of all spare parts and materials required for your maintenance. Register each spare part in the system and incorporate detailed and useful information such as cost, supplier, technical specifications or user manuals.

When repairing a machine, the consumed spare parts are automatically accounted for, so that we control the stock of available spare parts and know in advance when they need to be replaced.

Assign your mechanics each task

Create users with different levels of permissions for maintenance management and assign them to your staff: from administrators with full control to mechanics who can only see the maintenance orders assigned to them.

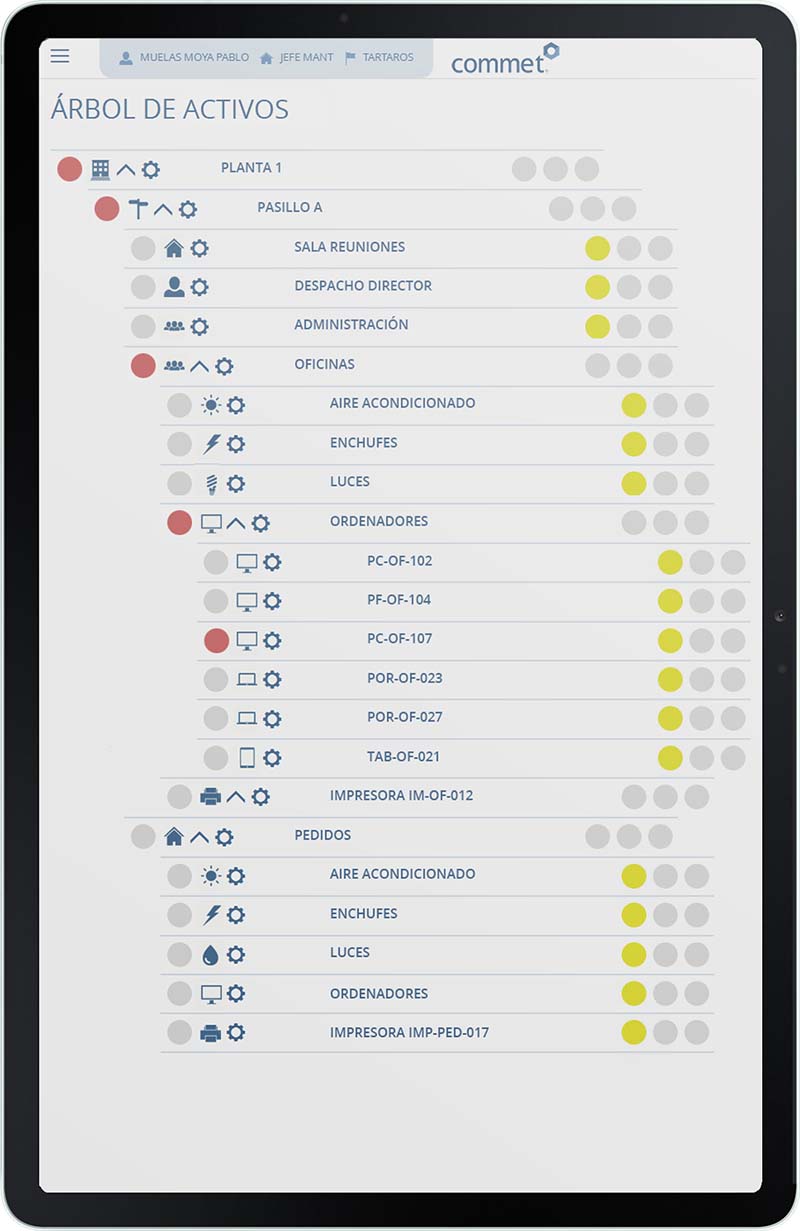

Machine tree view

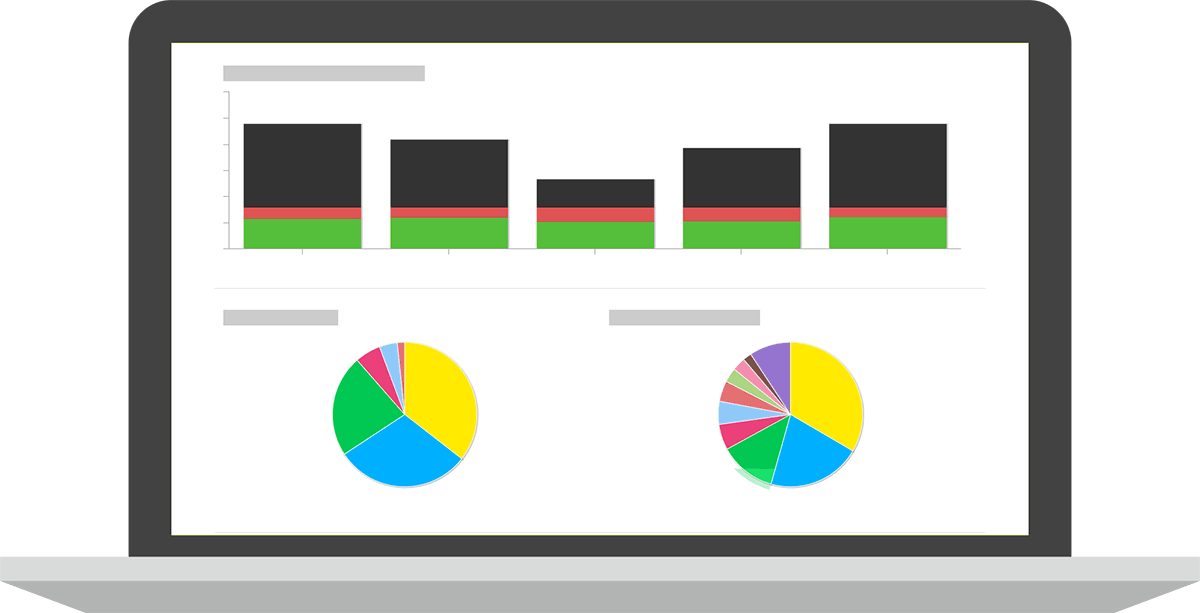

A complete CMMS maintenance analysis module

Analyze in depth all the key factors of your maintenance, such as the hours spent, personnel and spare parts costs, or the number of orders executed per type of maintenance or machine.

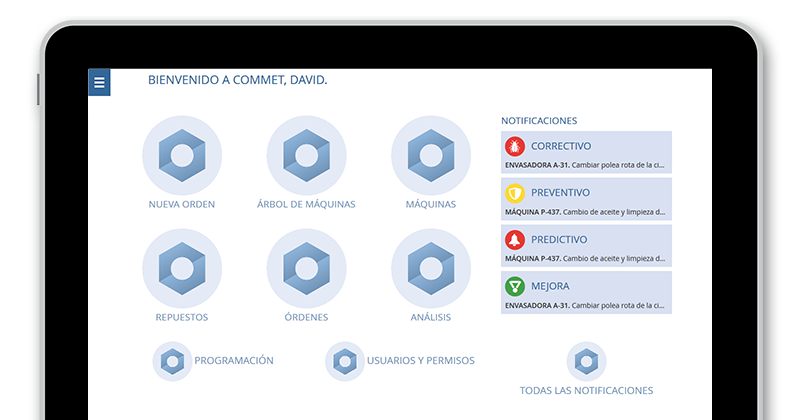

Open corrective orders quickly

Unintentional failures and breakdowns have a major impact on production processes because they cannot be planned for. What we can do is to have a rapid response to minimize its effects.

Open a corrective work order in just a few clicks when a critical failure occurs on your machines. Fill in the critical data and the mechanic will immediately receive the corrective maintenance order on his HMI.

Advantages of doeet CMMS maintenance

Create your preventive plans for machines or lines.

Create corrective commands in the event of an unforeseen failure.

Assign maintenance to your mechanics.

Associate manuals and checks to maintenance.

Manage the stock of your spare parts warehouse.

Analyze costs, time spent, MTBF or MTTR.

Associate documents and checks to CMMS maintenance

Associate files of all types with maintenance orders. In this way, we can associate documents such as an installation or maintenance manual, photos or videos to an order. We can also incorporate functions such as control of machine parameters, which we can verify later.

In this way, the mechanics have all the information they need to repair the breakdown and leave the machines ready and in optimum condition for production.

CMMS maintenance functions doeet

- Creation of preventive maintenance plans and programs.

- Quick creation and assignment of corrective maintenance.

- Assignment and management of maintenance orders to mechanics.

- Registration of users, levels and permissions.

- Maintenance reports by type, and costs.

- Spare parts stock control.

What is CMMS maintenance software?

A CMMS (Computer Aided Maintenance Management) software is a computer program that facilitates the maintenance management of an organization’s equipment and facilities.

The CMMS programs are composed of several interconnected modules that allow exhaustive control of the tasks to be carried out by the operators to facilitate the maintenance of the equipment and thus increase its productivity and extend its useful life.

Productive maintenance performed through CMMS is composed of several aspects such as the control of incidents or breakdowns, of which history is saved; the scheduling of revisions and preventive maintenance tasks for machines and installations; the control of stocks, spare parts and replacements; and the generation and follow-up of work orders for maintenance technicians.

CMMS programs provide a wealth of information that can be easily accessed. As a result, a history of each piece of equipment is created and predictive or preventive inspections are scheduled according to the parameters decided upon.

Phases in the implementation of CMMS maintenance software

The implementation of a CMMS system requires the realization of a well-directed process, which consists of the following phases:

Identification phase

Identification phase

Planning phase

Planning phase

Execution phase

Execution phase

Analysis phase

Analysis phase

- Coding of equipment through a tree structure containing all factory assets and the dependency relationships between them.

- Introduction of equipment and personnel into the system.

- Codification of tasks, especially those of a periodic nature to facilitate their scheduling. Subsequently, they must be entered into the system.

- Coding and entry of the system’s spare parts inventory. After this task, the stock available at the time of system start-up must be entered.

- Definition of the Scheduled Maintenance Plan and its introduction in the system. This step must always precede the implementation of the CMMS program. The system manages the maintenance plan previously designed by the personnel.

- Definition and creation of documents such as work orders, warehouse receipts and issues, improvement proposals and intervention reports.

- Design of the reports to be generated by the system. The information returned by the CMMS with the data entered is what allows appropriate decisions to be made. For this step to be useful, it must be very clear what information you want to obtain.

Other doeet solutions for Factory Plant Control